Conveyor Pulleys

Lorbrand design and manufacture a full range of in-plant to large overland conveyor pulleys to global industry standards.

Designed using proprietary software our conveyor pulleys are manufactured using high strength alloy steels to deliver a strong product designed for longevity.

Critical Stress areas in the conveyor pulley shafts and shells are thoroughly checked utilising the latest stress and finite analysis techniques. All conveyor pulleys are welded using the latest submerged arc technology, non-destructive tested and stress relieved.

When consulted early in the conveyor design process, we will work with you and your team to determine the best conveyor pulley design for the application.

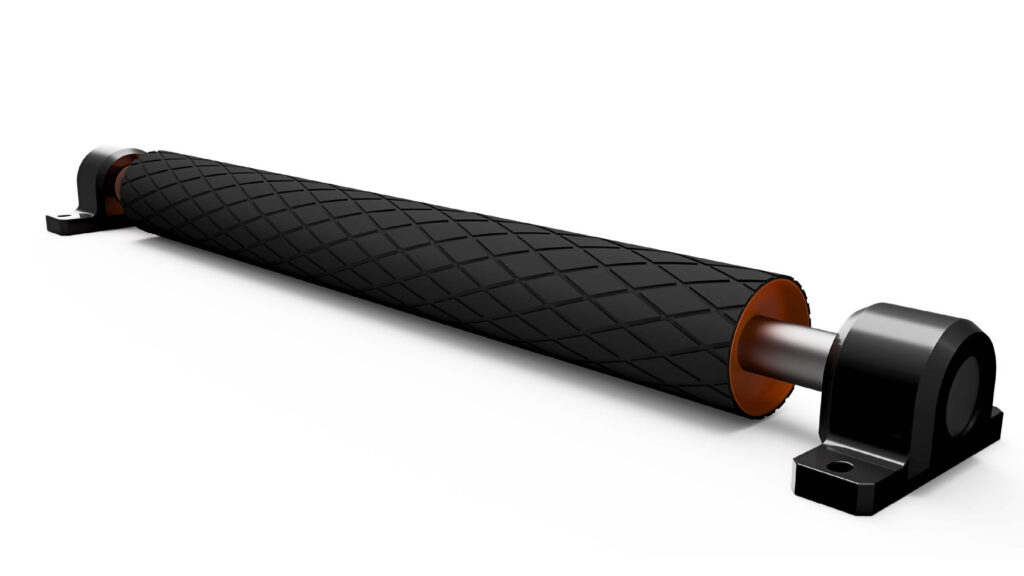

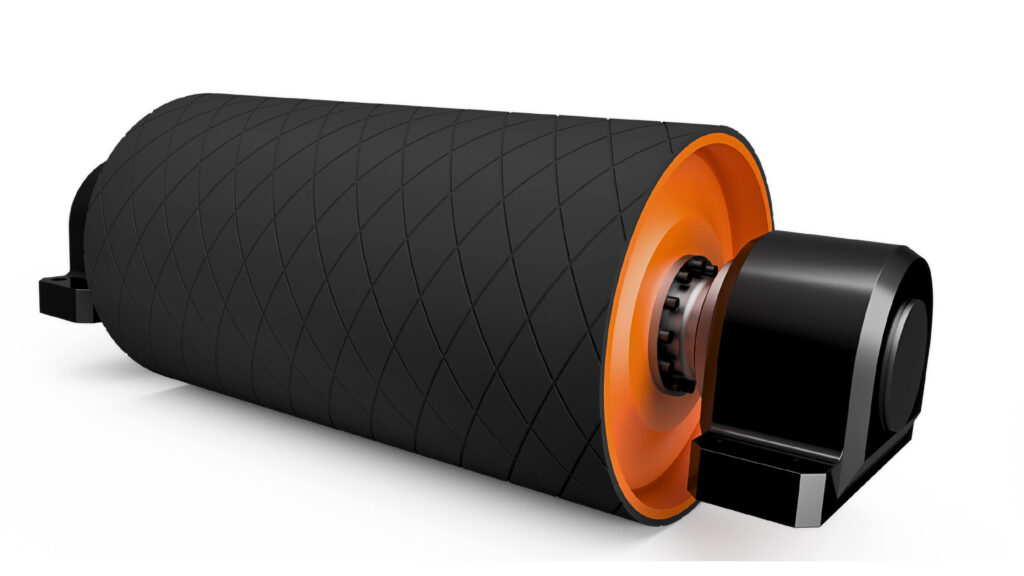

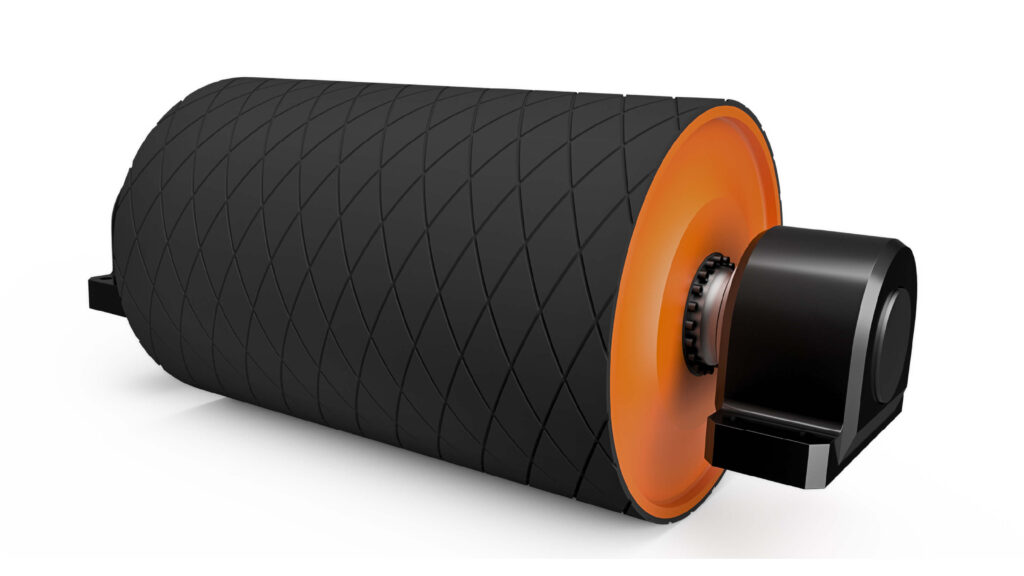

Lorbrand Conveyor Pulleys can be supplied with the following exterior or lagging options:

- Cold bonded rubber and ceramic lagging

- Direct bonded ceramic lagging

- Diamond grooved rubber lagging

- Hot vulcanized rubber lagging

- Plain rubber

- Plain steel

Pulley Assembly Features

- All welds ultrasonic and magnetic particle tested

- End discs are shot blasted and painted with marine specification paints

- Internal Flux-Cored welding and submerged arc external welds

- Shell thickness of up to 70mm and end plates up to 300mm

- Up to 2800mm in diameter

- Run out and deflection tolerances that exceed CEMA standards

- Smoothed and polished radii on shafts and end-plates to avoid stress risers

- FEA assessments available on request

- Thermal stress relieving

- Turbine, T-Bottom (engineered) pulleys & Apron Feeder Head Shaft Assemblies

Conveyor Pulleys Product Range

Live Shaft

Turbine

Engineered/T-Bottom