Conveyor Accessories

Lorbrand Australia offers a complete range of conveyor accessories.

Purpose built and designed to perform across all bulk materials applications, all our accessories built to perform in the harshest environments and operating conditions.

Conveyor Accessories Product Range

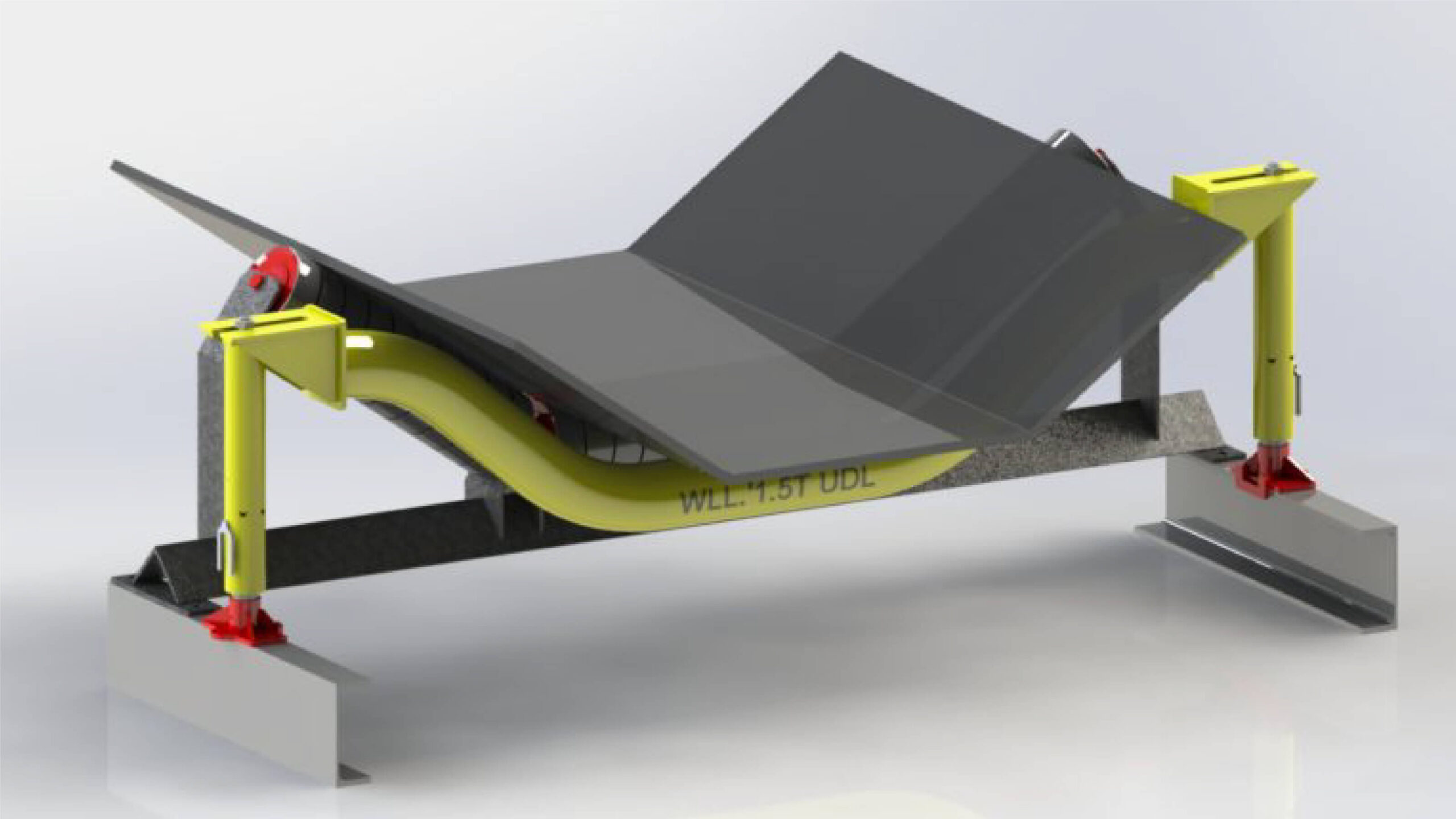

Hydraulic Conveyor Belt Lifters

- Hydraulic conveyor belt lifters are available in three models offering 1T, 1.5T or 2T capacity.

- Suitable for a range of conveyor belts between 900mm to 2500mm that are near flat and up to 50˚ trough angle.

- Effortlessly raises the belt in 30 to 45 seconds with minimal user interaction.

- Design incorporates a number of safety features preventing equipment overload and ensures no one works under a suspended load.

- Modular easy connect components stored in a heavy duty protective case.

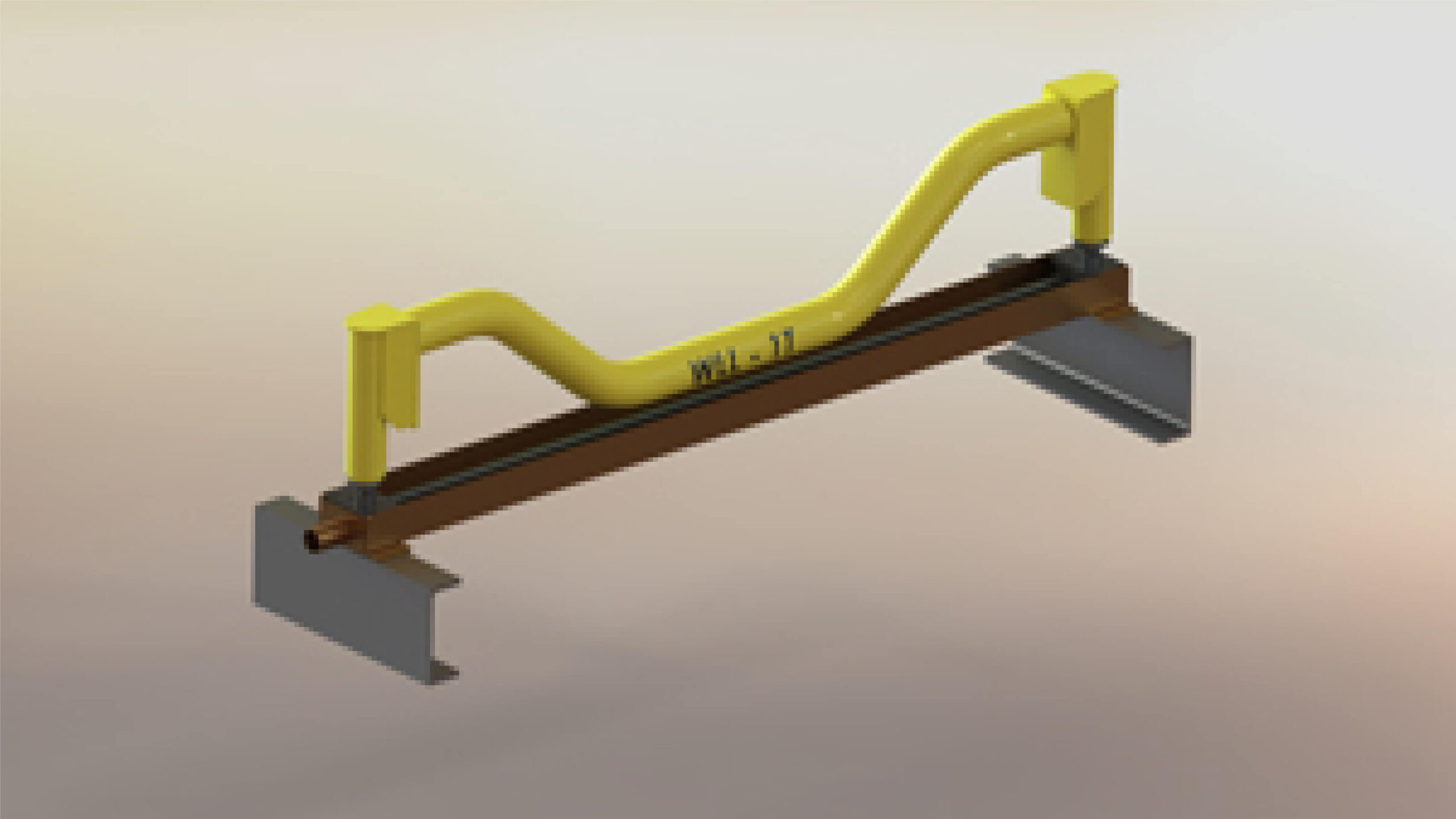

Mechanical Conveyor Belt Lifters

- Rated to a 1T dynamic lift capacity. Suitable for belt widths of 900mm to 1500mm for both 35˚ and 45˚ trough angles

- Raises the belt in 30-35 seconds using a high torque, low RPM driver

- Singular frame design can be positioned and operated on raised single walkway or when access is restricted in situations such as tunnels

-

2T static load capacity with a self-supporting anti reversing design allows a belt maintainer to safely work under the raised belt

All Lorbrand Australia belt lifters and beams are sourced locally from a third party.

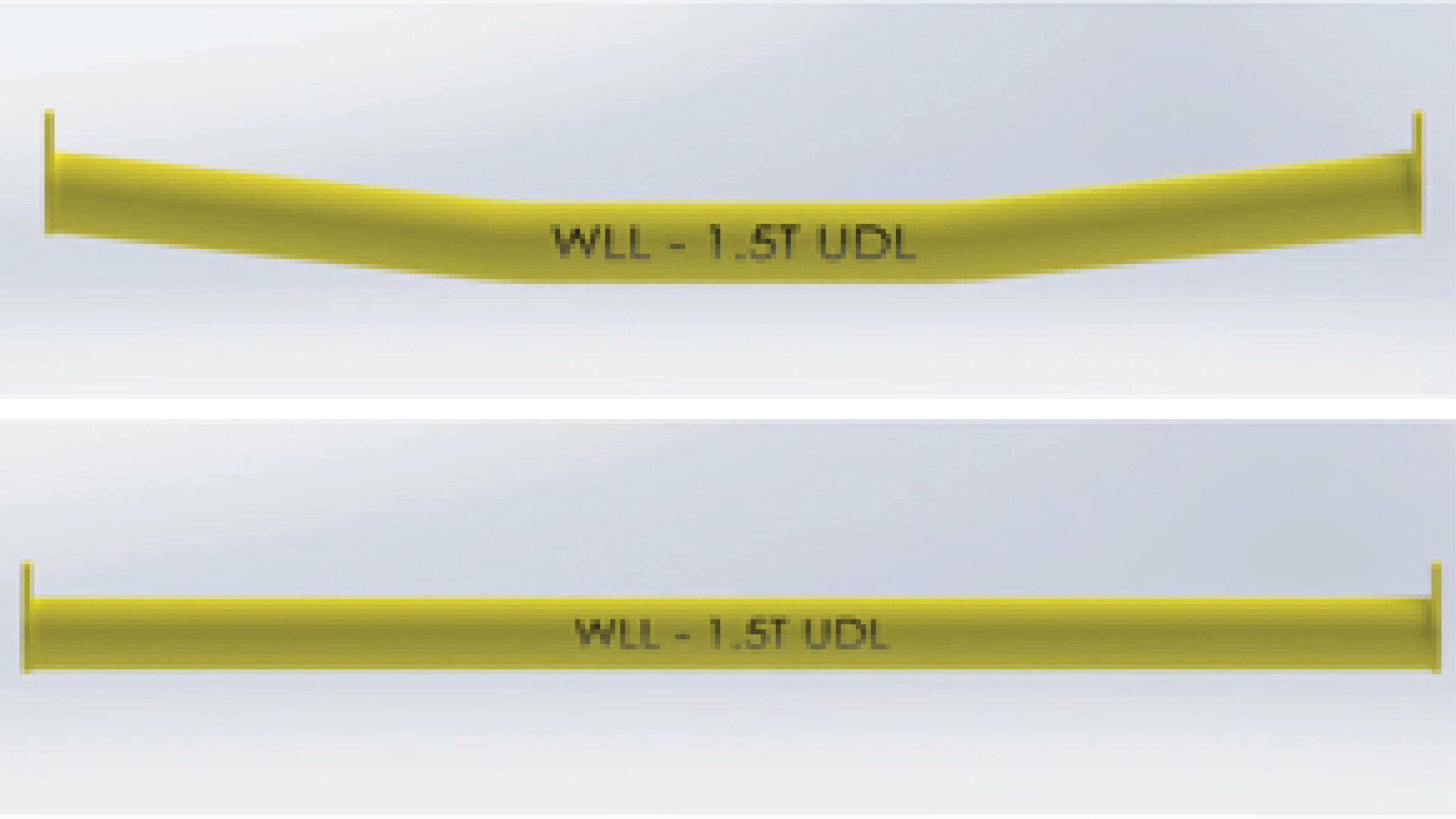

Lifting Beams

- Available in 1 or 1.5 Ton capacity across a range of belt sizes

- Designed for flat belts or contoured to fit v-return belts

- Fabricated to AS1654-2004 with full project traceability and Quality Control

- Proof load tested to twice the rated capacity by a NATA approved specialist

-

Fitted with unique product identification plates and is marked in bold, easy to read working load limit (WLL)

All Lorbrand Australia belt lifters and beams are sourced locally from a third party.

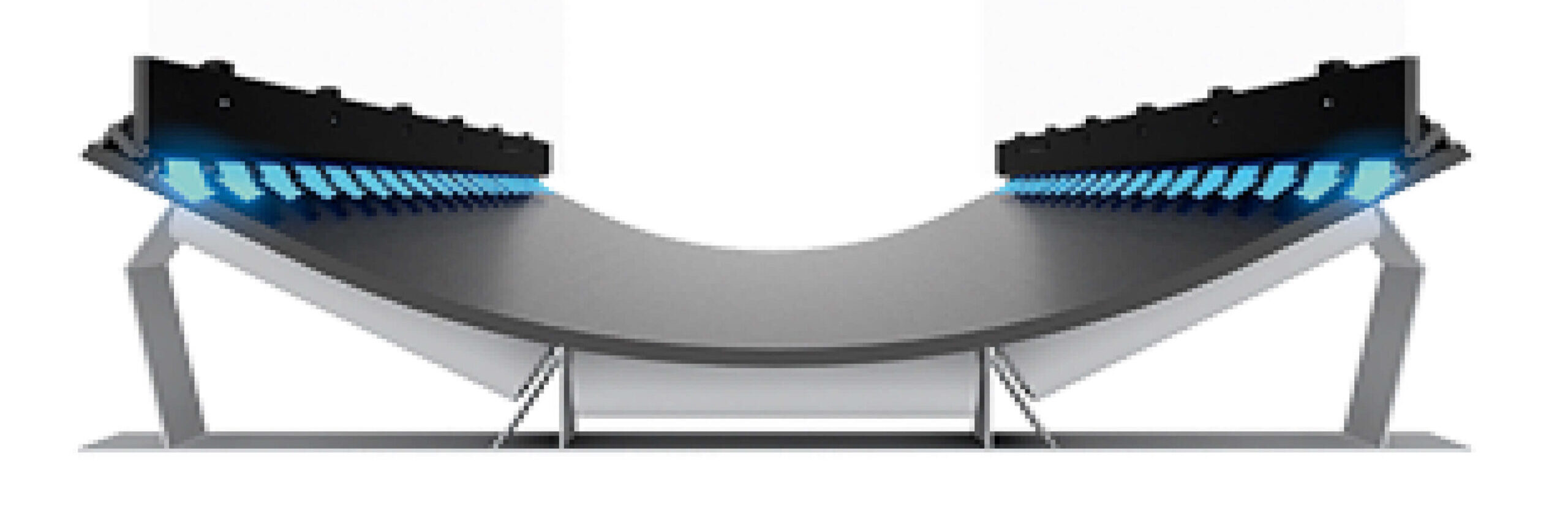

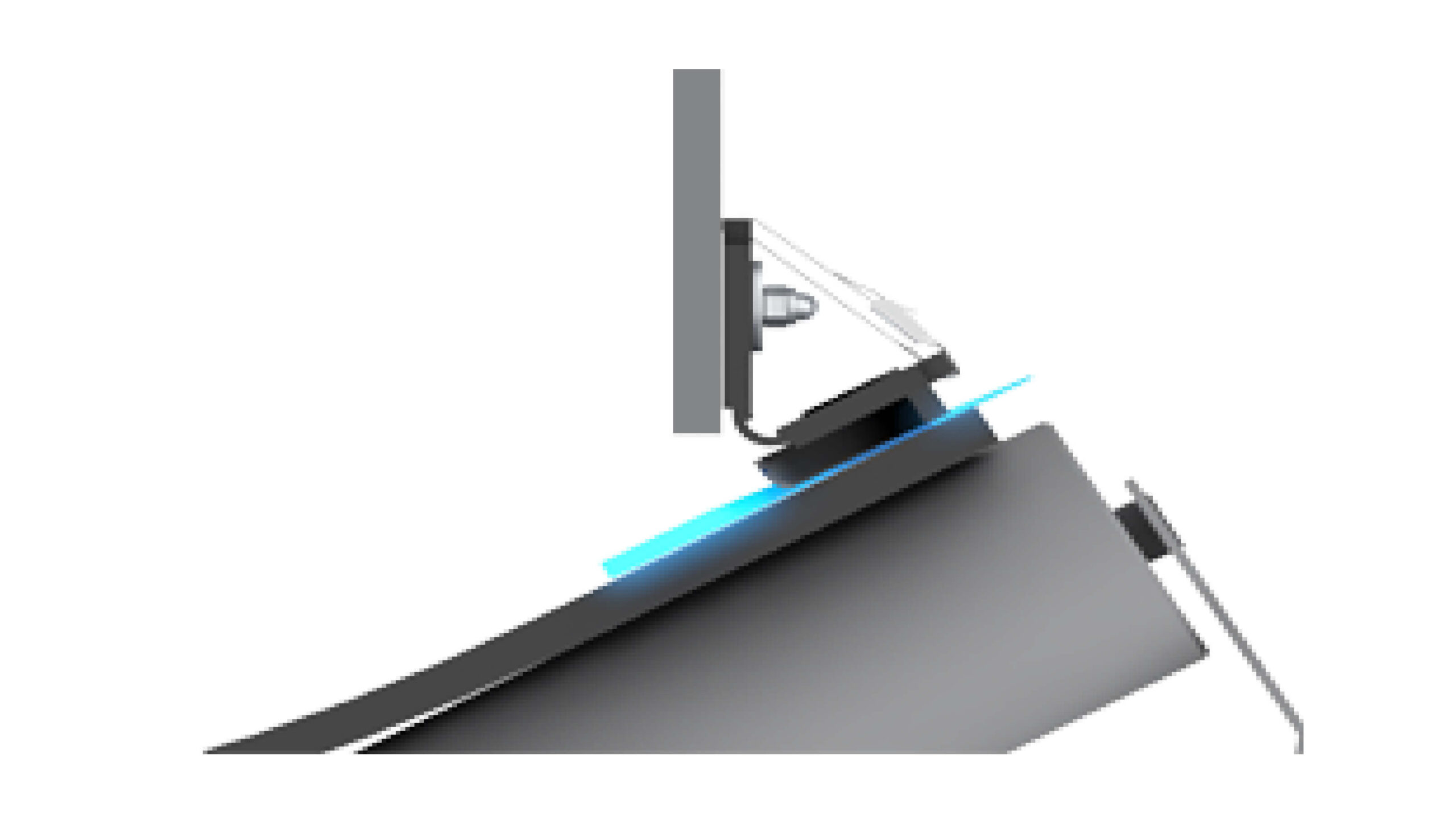

AirScrape Contact Free Conveyor Belt Skirting

AirScrape is a newly patented German designed and manufactured conveyor belt skirting system which hovers freely above the conveyor belt, eliminating skirt friction & belt damage.

It’s unique array of inward facing hardened steel diagonal blades, deflect larger particles inwards while it uses the airflow of the conveyor belt and conveyed material to create an inward suction, flowing any dust and fine particles back in to the product flow.

Download our product brochure here – Lorbrand Airscrape Skirting

- Minimises belt and skirt wear

- FRAS approved material for underground applications

- Hard wearing and long lasting polyutherane casing and Diagonal Hardox/Stainless Steel blades

- Quick Fit system for easy installation and adjustments

- Less risk for injuries

-

Superior, longer lasting and reliable cleaning for lower maintenance, breakdown and skirting costs

Airscrape is manufactured in Germany and sourced from a third party.

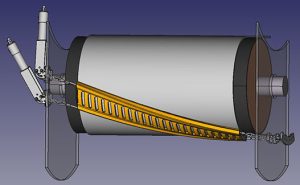

CleanScrape® Belt Cleaners, the newest and most effective belt cleaner to be released in the Australian market.

Designed and manufactured in Germany, CleanScrape® belt cleaners have challenged the traditional belt cleaner to deliver a revolutionary product which requires minimal maintenance while delivering up to 95% cleaning efficiency.

Across Australia CleanScrape® belt cleaners have already saved bulk materials handling applications thousands on reduced maintenance and equipment costs and in some instances eliminating carry back on belts altogether.

With installations across nearly all major commodities, the CleanScrape® has proven itself to reduce maintenance costs, downtime and improve cleaning efficiency, to view the CleanScrape® in action in visit our YouTube Channel or download our Product Brochure

Cleanscrape Primary Belt Cleaner

CleanScrape® is a primary cleaner which is installed diagonally across the discharge pulley and forms a three dimensional curve. The cleaner has a matrix of tungsten carbide scrapers incorporated into the main rubber body during the vulcanisation process. It is tensioned against the belt at an extremely low contact pressure. Due to its excellent cleaning performance, in many applications, the CleanScrape® belt cleaner often avoids the need for a secondary cleaner.

Cleanscrape belt cleaners are manufactured by Martin Engineering.

- Cleaning performance between 85% and 95% depending on material

- Low wear to the belt

- Suitable for all belt speeds with all types of mechanical joints

- Perfect solution for tight installation spaces

- Simple installation

- Suitable for reversing belts

Magnetic Repair Patch

Qik Patch is an innovative solution that provides a fast and simple way of repairing a hole in a chute, bin etc. without the need for any specialist tools or equipments.

Download our Qik Patch Fact Sheet

Conveyor Repair Kits

We supply a range of fast curing repair kits and accessories to repair fabric, steel cord and PVC conveyor belts.

Download our Conveyor Belt Repair Kits Catalogue